Overview

This set of devices is used for all kinds of chemical reagent high pressure injection system, including petrochemical, water treatment, medicine and so on.

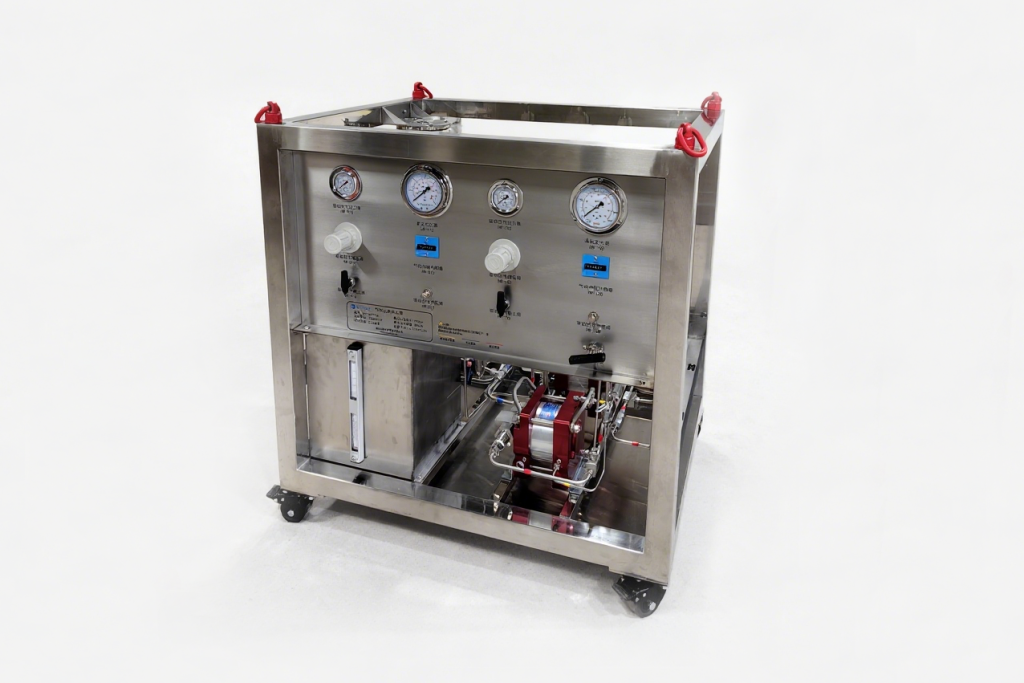

This set of devices mainly includes three functional modules:

(1)Manual operation panel: used to manually control the pressure and flow of the pneumatic pump injection;

(2)Stroke counting module: used to record the stroke times of the pneumatic pump in real time;

(3)Flow calibration module: used to calibrate the flow discharged by the pneumatic pump.

Model: WY-700C-TJ0

Top: Four rotating lifting rings are designed, with a single-side pulling load of 1.5T.

Bottom: Equipped with two fixed and two universal casters, each with a load capacity of 600KG;The ground clearance is 120 mm, and the hollowed-out area can be used as a jacking hole for equipment transportation.

Front: Designed with a driving air pressure control module, driving air flow control module, pneumatic stroke counter, high-pressure pressure gauge, high-pressure unloading valve, and liquid storage tank level gauge.

Model: WY-700C-TJ0

| Medium | Ethylene glycol |

| Overall dimensions | 1100L*900W*1200H |

| Max. Output Pressure | 70Mpa |

| Max. Output flow rate | 500L/h |

| Valve operating pressure | 137MPa |

| High-pressure pipeline size | 3/8 |

| Driving Air | 1/2NPT |

| External Liquid Supply | 1/2NPT |

| High – pressure Output | G1/4-120° |

| High – pressure Unloading | 1/2NPT |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————