Trolley Hydro Test Pumps: Benefits, Applications, and More

In the realm of industrial testing and quality assurance, the trolley hydro test pump stands out as a versatile and indispensable tool. This article delves into the intricacies of what a trolley hydro test pump is, explores its numerous benefits, identifies the user base, highlights its distinctive features, outlines various applications, discusses the associated benefits, and concludes with why Wingoil is a notable choice in this domain.

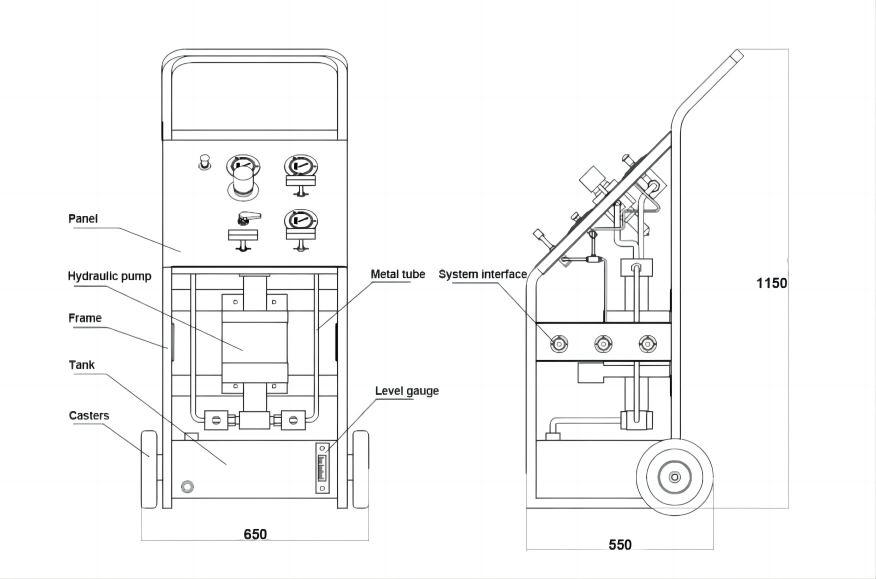

What is a Trolley Hydro Test Pump?

A trolley hydro test pump is a type of hydraulic pump that is used to test the pressure capacity of pipelines, hoses, pressure vessels, and other types of pressurized systems. Trolley hydro test pumps are typically lightweight and easy to transport, making them ideal for use in a variety of settings. They are also powered by low-pressure compressed air, making them safe and environmentally friendly.

What are the Benefits of Using a Trolley Hydro Test Pump?

Trolley hydro test pumps offer a number of benefits over other methods of hydro testing, including:

- Accuracy and reliability: Trolley hydro test pumps are highly accurate and reliable, and they can generate precise test pressures. This is because trolley hydro test pumps use a variety of sensors and feedback mechanisms to ensure that the test pressure is held to a very tight tolerance. This is important because inaccurate test results can lead to serious safety problems.

- Safety and control: Trolley hydro test pumps provide a safe and controlled testing environment. This is because trolley hydro test pumps are equipped with a variety of safety features, such as pressure relief valves, emergency stop switches, and interlocks. These safety features help to prevent accidents and injuries during hydro testing.

- Ease of use and maintenance: Trolley hydro test pumps are easy to use and maintain. This is because trolley hydro test pumps are typically designed to be user-friendly and require minimal training to operate. Additionally, trolley hydro test pumps are typically made with high-quality components that require very little maintenance.

- Cost-effectiveness: Trolley hydro test pumps are a cost-effective way to hydro test pressurized systems. This is because trolley hydro test pumps are relatively inexpensive to purchase and operate, and they can be used to test a wide variety of pressurized systems. Additionally, trolley hydro test pumps can help reduce the downtime of pressurized systems by providing a quick and easy way to test the pressure integrity of these systems.

Who Uses Trolley Hydro Test Pumps?

Trolley hydro test pumps are used by a wide range of industries, including:

- Construction: Trolley hydro test pumps are used to test the pressure integrity of pipelines, pressure vessels, and other types of equipment used in the construction industry. This is important because construction equipment is often subjected to high pressures, and a failure of this equipment can lead to serious safety problems.

- Oil and gas: Trolley hydro test pumps are used to test the pressure integrity of pipelines, wellheads, and other types of equipment used in the oil and gas industry. This is important because the oil and gas industry deals with highly pressurized fluids, and a failure of this equipment can lead to serious safety and environmental problems.

- Power generation: Trolley hydro test pumps are used to test the pressure integrity of boilers, turbines, and other types of equipment used in the power generation industry. This is important because power generation equipment is often subjected to high pressures and temperatures, and a failure of this equipment can lead to serious safety and environmental problems.

- Manufacturing: Trolley hydro test pumps are used to test the pressure integrity of a variety of products, such as automotive components, aerospace components, and medical devices. This is important because these products are often subjected to high pressures during use, and a failure of these products can lead to serious safety problems.

Applications of Trolley Hydro Test Pumps

Trolley hydro test pumps can be used for a variety of applications, including:

- Hydrostatic testing of pipelines, hoses, pressure vessels, and other types of pressurized systems: Trolley hydro test pumps are commonly used to test the pressure integrity of pipelines, hoses, pressure vessels, and other types of pressurized systems. This is important because it helps to ensure that these systems can withstand the pressures that they will be subjected to during use.

- Leak testing: Trolley hydro test pumps can also be used to detect leaks in pressurized systems. This is important because leaks can lead to a number of problems, including safety problems, environmental problems, and financial losses.

- Performance testing: Trolley hydro test pumps can also be used to test the performance of pressurized systems. This is important because it helps to ensure that these systems are operating properly and efficiently.

- Safety inspections: Trolley hydro test pumps can also be used to conduct safety inspections of pressurized systems. This is important because it helps to identify potential safety problems before they can lead to accidents or injuries.

Why Choose a Trolley Hydro Test Pump from Wingoil?

In the realm of trolley hydro test pumps, Wingoil stands out as a reliable and innovative provider. With a commitment to quality, safety, and sustainability, Wingoil’s products embody the key features and benefits discussed in this article. Choosing a trolley hydro test pump from Wingoil ensures not only the efficiency of testing procedures but also a partnership with a trusted industry leader.

In conclusion, the trolley hydro test pump is a pivotal tool in the landscape of industrial testing, offering mobility, precision, and versatility. As industries continue to prioritize safety, efficiency, and sustainability, the trolley hydro test pump emerges as a solution that aligns with these values, ensuring the reliability and longevity of pressurized systems.