Wingoil High Pressure Hydraulic Burst Testing Cabinet PLC Control Data Recording

- It’s a state-of-the-art testing solution designed to simulate extreme pressure conditions, ensuring the reliability and safety of hydraulic systems and components.

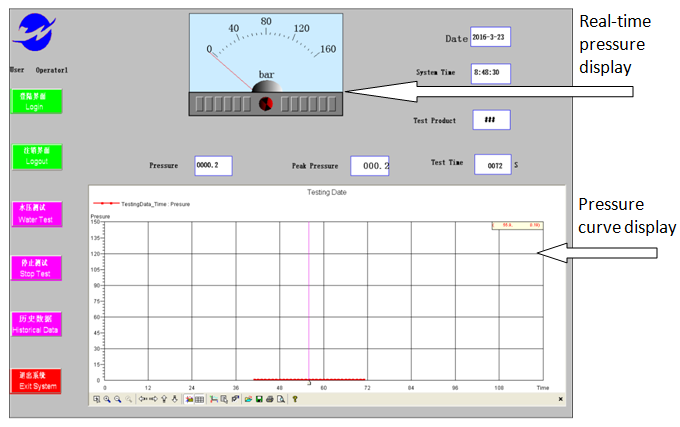

- The data recording feature of the cabinet enables users to capture and analyze test data in real-time, providing valuable insights into the performance and behavior of the tested components. This data can be used to optimize system design, identify potential failures, and improve overall system reliability.

Share to

Overview

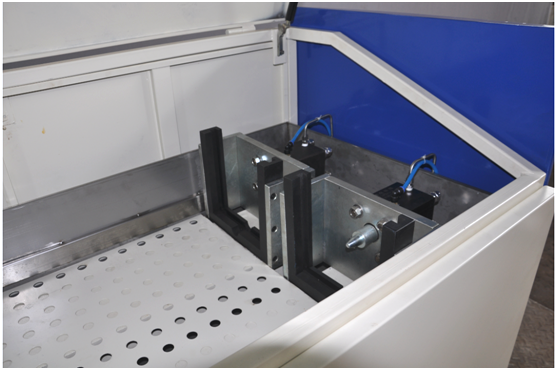

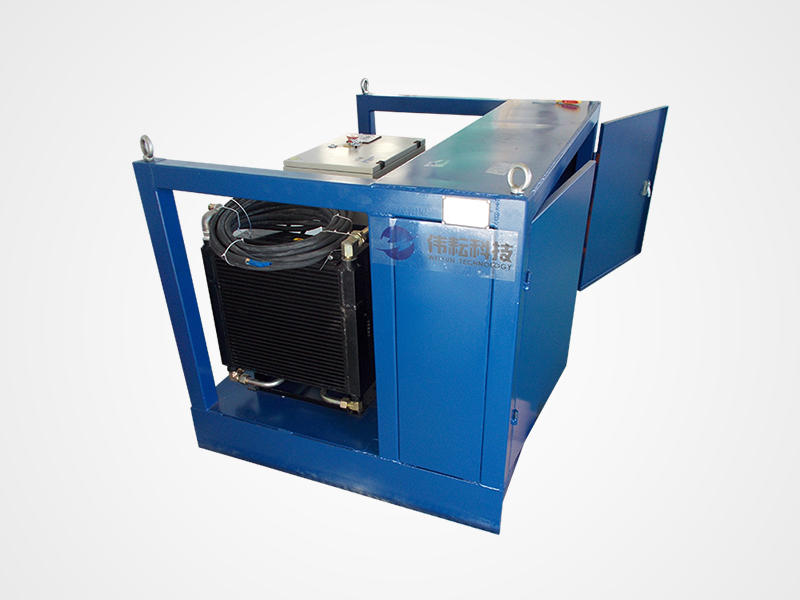

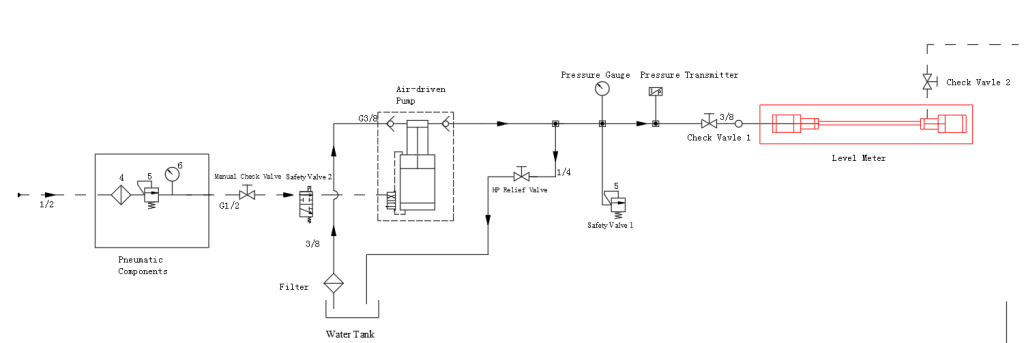

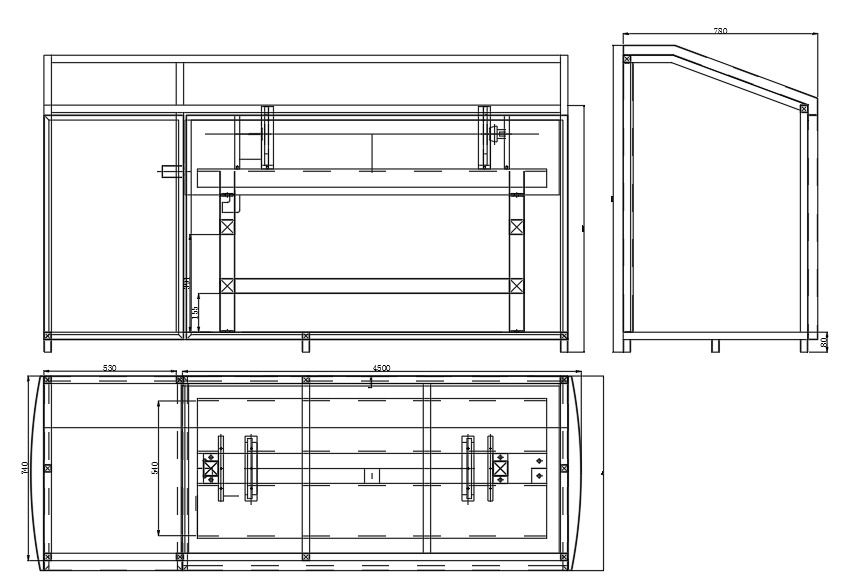

Wingoil High Pressure Hydraulic Testing Cabinet(high pressure hose testing equipment) is consisted of a set of Pneumatic Hydro Testing Pump System, a set of Data Acquisition System (PLC), and Toolings and the cabinet. It can be used for hose, gauge, pipe, or valve hydro testings.

Data Acquisition & Recording

| Max. outlet pressure | 280 bar @ 6-7 bar of driving-air |

| Max. flow rate | 1.02L/min |

| Overall dimension | 5100L*740W*1200H (mm) |

| Driving by | Compressed air |

| Safety valve pressure | 270 bar |

| Ball valve pressure | 412 bar |

| Sensor pressure | 400 bar |

| Sensor accuracy | ±0.1%FS |

| Pressure gauge range | 0 to 600 bar |

| Tested workpiece | Max. 4.2 meters length |

| Water inlet | G1/2 F |

| HP outlet | NPT3/8 |

| Bleeding off | G1/4 F |

| Compressed air inlet | G1/2 |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————