A Guide to Wingoil’s Portable Hydrostatic Test Pumps

In various industries, the integrity of pipes, valves, and pressure vessels is paramount. These components play a vital role in countless applications, from plumbing systems in buildings to pipelines transporting hazardous materials. To ensure their safe operation, regular inspections and testing are crucial. Hydrostatic testing is a non-destructive testing method that plays a critical role in verifying the structural integrity of pressure vessels. It involves pressurizing the vessel with a liquid, typically water, to a predetermined level exceeding its normal operating pressure. By observing for leaks or deformations, technicians can identify potential weaknesses before they escalate into catastrophic failures.

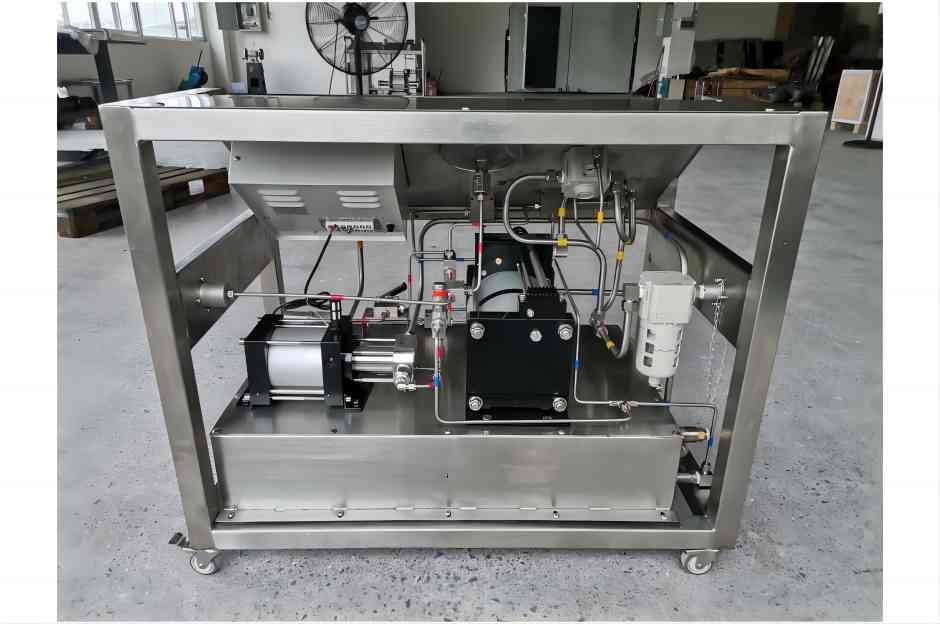

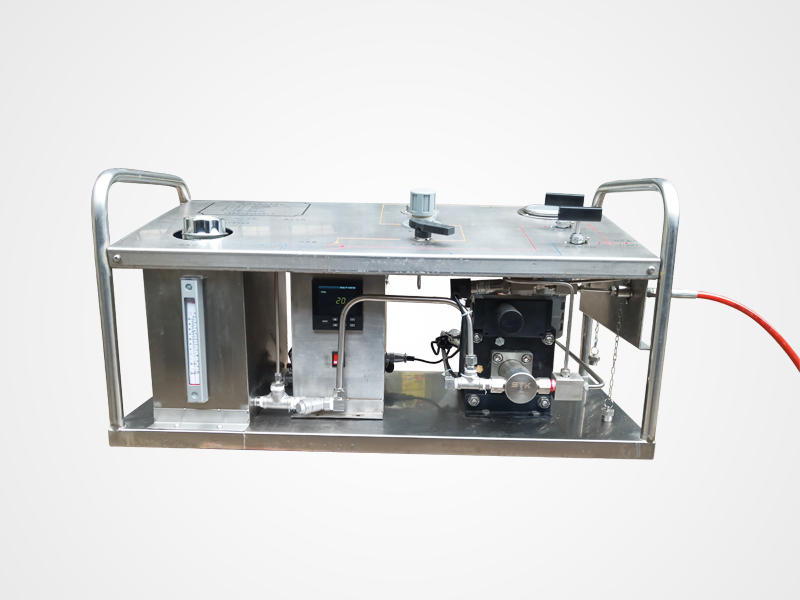

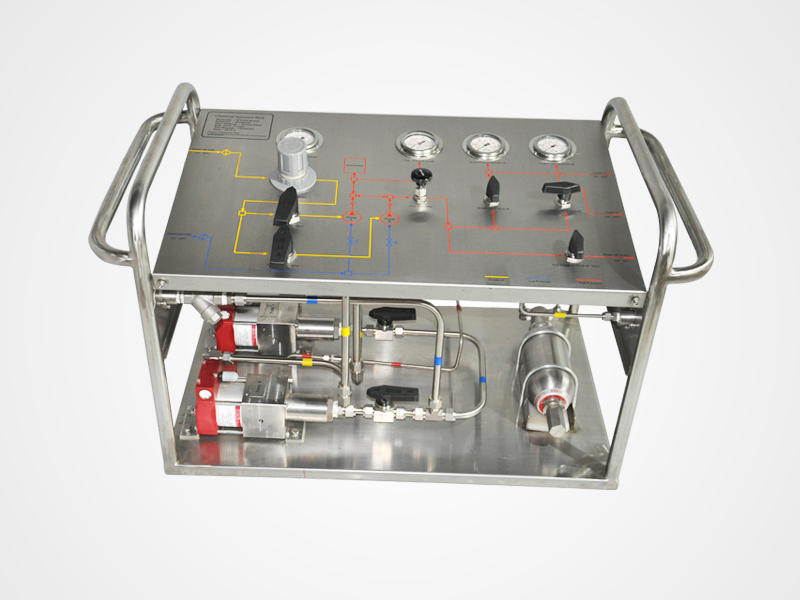

Wingoil is a company dedicated to providing reliable equipment for pressure testing applications. Their focus lies on portable hydrostatic test pumps, offering solutions for professionals who require on-site testing capabilities. This article explores the different types of portable hydrostatic test pumps available, highlighting their advantages and limitations. We will then delve into how this information applies to Wingoil’s offerings and explore methods to identify the most suitable pump for your specific needs.

Understanding Portable Hydrostatic Test Pumps

Portable hydrostatic test pumps are self-contained units designed to generate high-pressure fluid for testing pressure vessels. They come in various configurations, each with its own set of characteristics and applications. Here, we will explore the four main types of portable hydrostatic test pumps:

1. Manual Handheld Test Pumps: As the name suggests, manual handheld test pumps are the most basic type. They require manual operation to generate pressure through a handle or lever mechanism. The user creates pressure by repeatedly moving the handle, forcing fluid into the test system.

- Advantages: Manual handheld pumps are the simplest and most portable option. They are relatively inexpensive and require minimal maintenance. Additionally, they are well-suited for low-pressure applications where high power output is not necessary.

- Limitations: The primary limitation of manual handheld pumps is their limited pressure output. They are not ideal for testing high-pressure systems. Additionally, generating high pressure requires significant manual effort, making them less suitable for prolonged testing or situations where fatigue might be a factor.

2. Electric Motor-Driven Test Pumps: Electric motor-driven test pumps offer a significant advantage over manual pumps in terms of convenience and power output. They utilize an electric motor as the power source, eliminating the need for manual operation. The user controls the pump through a control panel, allowing for precise pressure regulation and easier test execution.

- Advantages: Electric motor-driven pumps offer significantly higher pressure output compared to manual pumps. They are also much easier to operate, reducing user fatigue and improving test efficiency. The control panel allows for precise pressure control, ensuring accurate test results.

- Limitations: Electric motor-driven pumps rely on an external power source, limiting their use in locations without access to electricity. Additionally, they tend to be heavier and bulkier than manual pumps, affecting portability to some extent.

3. Gasoline/Diesel Engine-Powered Test Pumps: For situations requiring high-pressure output and portability, gasoline/diesel engine-powered test pumps are the preferred choice. These pumps utilize an internal combustion engine as the power source, allowing them to operate independently of an external power supply.

- Advantages: Gasoline/diesel engine-powered pumps are capable of generating the highest pressure output among the portable options. They are ideal for testing high-pressure systems in remote locations without access to electricity. Their portability makes them suitable for on-site testing needs.

- Limitations: The primary drawbacks of gasoline/diesel engine-powered pumps are noise and emissions. Additionally, they require regular maintenance to ensure optimal performance, and fuel storage and handling need to be considered.

4. Pneumatic Test Pumps: For low-pressure applications such as leak testing and flushing systems, pneumatic test pumps offer a simple and efficient solution. They utilize compressed air as the power source, making them lightweight and portable.

- Advantages: Pneumatic test pumps are exceptionally lightweight and easy to operate. They are ideal for low-pressure applications and situations requiring frequent movement between testing locations. Additionally, they do not require electricity or generate emissions, making them suitable for use in confined spaces.

- Limitations: The primary limitation of pneumatic test pumps is their pressure output, which is significantly lower compared to other pump types. They are not suitable for testing high-pressure systems. Additionally, they rely on an external compressed air source, which may not always be readily available.

Selecting the Right Portable Hydrostatic Pressure Test Pump from Wingoil

While the categories mentioned above provide a general overview of portable hydrostatic pressure test pumps, it is important to understand that they might not directly correspond to specific models offered by Wingoil. Their website might categorize their pumps based on different criteria, such as pressure output, flow rate, or specific application. Here’s how to determine the most suitable Wingoil pump for your needs:

1. Understanding Your Testing Requirements: The first step is to clearly define the testing requirements of your application. Here are some key factors to consider:

- Pressure Rating: Identify the maximum pressure you need to achieve during testing. The pump’s pressure rating should comfortably exceed this value to ensure a safe and effective test.

- Volume of the System Being Tested: The size of the pressure vessel or system you are testing will influence the pump’s flow rate requirements. Larger systems require pumps with higher flow rates to fill them efficiently and reach the desired pressure within a reasonable timeframe.

- Portability Needs: Consider the test environment and accessibility. If you require maximum portability for frequent movement between test locations, a lightweight and compact pump might be a priority.

- Power Source Availability: Evaluate the availability of a reliable power source at the testing location. If electricity is readily available, an electric motor-driven pump might be a good choice. For remote locations, a gasoline/diesel engine-powered pump might be necessary.

2. Researching Wingoil’s Offerings: Once you have a clear understanding of your testing requirements, explore Wingoil’s website or contact them directly to gather information on their specific portable hydrostatic test pump models. Here are some resources to help you:

- Wingoil Website: The Wingoil website might offer product catalogs, brochures, or technical specifications for their pumps. Look for details such as pressure ratings, flow rates, power source requirements, weight and dimensions, and any included features.

- Contacting Wingoil: If the website information is not sufficient, contacting Wingoil directly through phone or email allows you to discuss your specific needs with a knowledgeable representative. They can recommend suitable pump models based on your application and answer any questions you might have.

Additional Considerations for Safe and Effective Hydrostatic Testing

Selecting the right pump is crucial, but it’s just one aspect of safe and effective hydrostatic testing. Here are some additional considerations:

- Safety Precautions: Hydrostatic testing involves pressurizing equipment beyond its normal operating pressure. Always prioritize safety by following established protocols and adhering to manufacturer recommendations for the specific equipment being tested. Utilize appropriate personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection (for engine-powered pumps).

- Test Procedures: Develop a clear and well-defined test procedure outlining the steps involved in the testing process. This should include pre-test preparation, pressure application procedures, leak detection methods, and safe pressure release protocols.

- Data Recording: Document the entire testing process, including the pressure readings, observations made during the test, and any deviations from the established procedure. This data serves as a record for future reference and ensures traceability in case of any issues.

Conclusion

Portable hydrostatic test pumps are valuable tools for ensuring the safety and integrity of pressure vessels in various industries. By understanding the different types of pumps available and their respective advantages and limitations, you can select the most suitable option for your specific needs. Wingoil offers a range of portable hydrostatic test pumps, and by carefully analyzing your testing requirements and utilizing the resources provided, you can identify the Wingoil pump that best fits your application. Remember, prioritizing safety and following established testing procedures is paramount for successful and risk-free hydrostatic testing.