Exploring the Different Materials Used in Dissolvable Frac Plugs

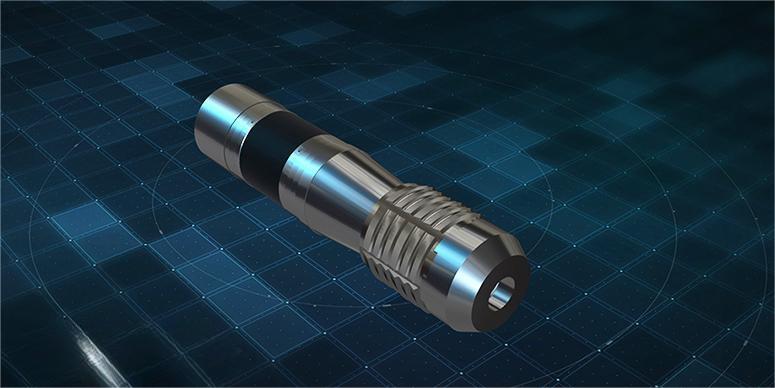

In the realm of hydraulic fracturing, dissolvable frac plugs play a pivotal role in optimizing wellbore integrity and enhancing production efficiency. These plugs are designed to temporarily isolate sections of the wellbore during the fracturing process and are subsequently dissolved, eliminating the need for costly retrieval operations. This article aims to provide a comprehensive guide to the various types of dissolvable frac plugs categorized by the materials used.

Types of Dissolvable Frac Plugs by Materials

- Polymer-Based Dissolvable Frac Plugs

Polymer-based dissolvable frac plugs utilize synthetic polymers such as Polyglycolic Acid (PGA), Poly(lactic-co-glycolic acid) (PLGA), and Polyvinyl Alcohol (PVA). These materials offer excellent mechanical strength, chemical resistance, and controlled degradation characteristics. PGA dissolvable frac plugs are known for their high strength and rapid degradation, making them suitable for short-term isolation requirements. PLGA dissolvable frac plugs strike a balance between strength and degradation rate, allowing for customized plug performance. PVA dissolvable frac plugs possess high dissolvability in water-based fluids and are often used in low-temperature applications.

- Metallic Dissolvable Frac Plugs

Metallic dissolvable frac plugs are constructed using metals such as magnesium alloys, zinc alloys, and iron-based materials. These metal frac plugs offer robust mechanical properties and high resistance to wellbore conditions. Magnesium alloy dissolvable frac plugs excel in high-temperature environments, as they exhibit excellent corrosion resistance and controlled dissolution rates. Zinc alloy dissolvable frac plugs provide reliable dissolvability and are often favored for their cost-effectiveness. Iron-based dissolvable frac plugs offer superior mechanical strength and can withstand harsh wellbore conditions, making them suitable for demanding applications.

- Composite Dissolvable Frac Plugs

Composite dissolvable frac plugs combine different materials to harness their collective advantages. Fiber-reinforced composites, such as carbon fiber-reinforced polymers (CFRP), offer exceptional strength-to-weight ratios and resistance to chemical degradation. These plugs are highly customizable and can be tailored for specific wellbore conditions. Ceramic matrix composites (CMC) provide excellent resistance to thermal and chemical stresses, making them suitable for extreme environments. CMC dissolvable frac plugs exhibit controlled dissolution properties, ensuring effective isolation during fracturing operations.

Polymer-Based Dissolvable Frac Plugs in Detail

- Polyglycolic Acid (PGA) Dissolvable Frac Plugs

PGA is a biodegradable polymer that degrades rapidly in the presence of water, making it ideal for short-term isolation. Its high strength allows for effective wellbore sealing, and its rapid dissolution eliminates the need for plug retrieval. PGA dissolvable frac plugs find applications in wells with limited operational timeframes, reducing overall costs. However, PGA’s limitations lie in its sensitivity to temperature, which may affect its performance in high-temperature environments.

- Poly(lactic-co-glycolic acid) (PLGA) Dissolvable Frac Plugs

PLGA is a copolymer that offers controlled degradation and tunable mechanical properties. PLGA dissolvable frac plugs provide customizable plug performance, allowing for tailored dissolution rates and strength requirements. Its versatility enables its application in various wellbore conditions. However, PLGA’s degradation rate is slower than PGA, necessitating longer isolation times in comparison.

- Polyvinyl Alcohol (PVA) Dissolvable Frac Plugs

PVA is a water-soluble polymer known for its high dissolvability in water-based fluids. PVA dissolvable frac plugs are particularly suited for low-temperature applications, as they dissolve rapidly, leaving no residue. Their compatibility with water-based fluids makes them an excellent choice for operations where residue elimination is critical. However, PVA dissolvable frac plugs may have limitations in high-temperature environments due to their lower thermal stability.

Metallic Dissolvable Frac Plugs in Detail

- Magnesium Alloy Dissolvable Frac Plugs

Magnesium alloy dissolvable frac plugs offer exceptional corrosion resistance and controlled dissolution rates. They perform well in high-temperature environments and exhibit robust mechanical strength. These plugs are commonly used in wells with demanding conditions, where prolonged isolation and reliable dissolution are crucial. However, magnesium alloy dissolvable frac plugs can be more expensive compared to other materials.

- Zinc Alloy Dissolvable Frac Plugs

Zinc alloy dissolvable frac plugs provide cost-effective solutions without compromising dissolvability. They offer reliable performance and are suitable for a wide range of wellbore conditions. Zinc alloy dissolvable frac plugs are favored for their economical value and ability to dissolve in various fluids. However, they may have limitations in extreme temperatures or corrosive environments.

- Iron-Based Dissolvable Frac Plugs

Iron-based dissolvable frac plugs are known for their superior mechanical strength and resilience to harsh wellbore conditions. They offer reliable isolation and dissolution properties, making them suitable for demanding applications. Iron-based dissolvable frac plugs excel in high-pressure and high-temperature environments. However, their dissolution rates may be slower compared to other materials, and they may require a longer timeframe for complete dissolution.

Composite Dissolvable Frac Plugs in Detail

- Fiber-Reinforced Composite Dissolvable Frac Plugs

Fiber-reinforced composites, such as carbon fiber-reinforced polymers (CFRP), provide a combination of strength and lightness. These dissolvable frac plugs offer excellent resistance to corrosion and chemical degradation, as well as customizable dissolution rates. CFRP dissolvable frac plugs are highly versatile and can be tailored to specific wellbore conditions. However, their production costs may be higher compared to other materials.

- Ceramic Matrix Composite Dissolvable Frac Plugs

Ceramic matrix composites (CMC) offer exceptional resistance to thermal and chemical stresses. These dissolvable frac plugs are suitable for extreme environments, providing reliable isolation and controlled dissolution. CMC dissolvable frac plugs exhibit high strength and stability, making them ideal for wells with challenging conditions. However, their manufacturing complexity and costs may be higher compared to other materials.

Conclusion

In conclusion, the choice of material for dissolvable frac plugs depends on specific wellbore conditions, isolation requirements, dissolution rates, and cost considerations. Polymer-based dissolvable frac plugs, such as PGA, PLGA, and PVA, offer different strengths and degradation rates. Metallic dissolvable frac plugs, including magnesium alloys, zinc alloys, and iron-based materials, provide robustness and resistance to wellbore conditions. Composite dissolvable frac plugs, such as fiber-reinforced composites and ceramic matrix composites, combine materials to harness unique advantages.

As technology advances, further research and development may lead to new materials and improvements in dissolvable frac plug performance. Understanding the characteristics and limitations of each material type is crucial for selecting the appropriate dissolvable frac plug to optimize hydraulic fracturing operations and ensure efficient wellbore integrity.