How to Use an Air Compressor Skid with a Hose Pressure Testing Machine?

An air compressor skid with a hose pressure testing machine is a valuable piece of equipment used in various industries to ensure the safety and reliability of hoses and pipelines. This combination of tools allows for the pressurized testing of hoses to check for leaks, weaknesses, or faults. In this article, we will explore what an air compressor skid with a hose pressure testing machine is, its benefits, and safety precautions, and provide step-by-step instructions on how to use it effectively.

What is an Air Compressor Skid with a Hose Pressure Testing Machine?

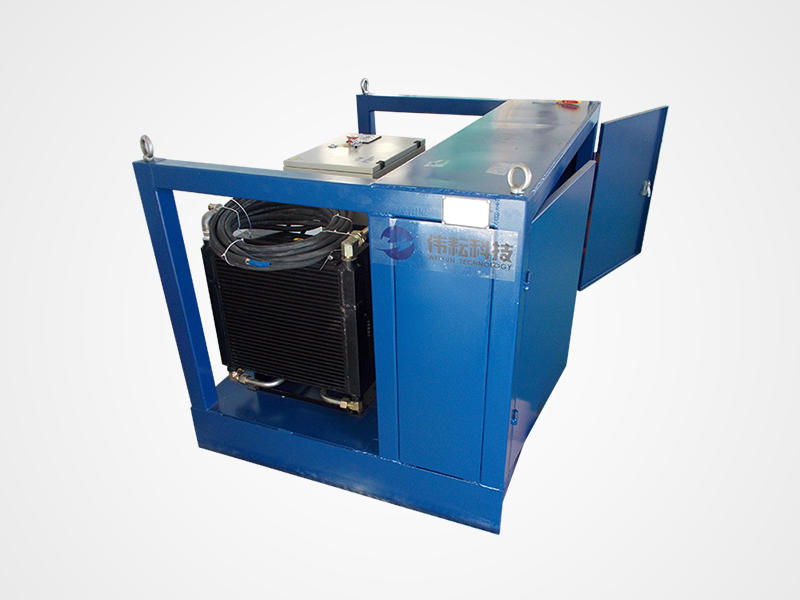

An air compressor skid with a hose pressure testing machine is a comprehensive system designed to test the integrity of hoses and pipelines by subjecting them to controlled pressure. The key components of this setup include an air compressor skid and a hose pressure testing machine.

Air Compressor Skid: This component generates compressed air to pressurize the hose for testing. It typically includes an air compressor, control panel, pressure gauges, and safety features.

Hose Pressure Testing Machine: This machine is responsible for controlling and monitoring the pressure applied to the hose under test. It features valves, pressure gauges, and a pressure release mechanism.

Benefits of Using an Air Compressor Skid with a Hose Pressure Testing Machine

Using this equipment offers several advantages:

- Safety Assurance: It helps identify potential weaknesses or defects in hoses before they are put into service, reducing the risk of accidents or leaks.

- Quality Control: Ensures the quality and reliability of hoses, meeting industry standards and regulations.

- Cost Savings: Identifying and repairing faulty hoses before deployment saves money in the long run by preventing costly downtime, accidents, and replacements.

- Efficiency: Speeds up the testing process and ensures accurate results.

Safety Precautions When Using an Air Compressor Skid with a Hose Pressure Testing Machine

Before using an air compressor skid with a hose pressure testing machine, it is crucial to prioritize safety. Here are some essential precautions to take:

- Read the User Manual: Familiarize yourself with the user manual of both the air compressor skid and the hose pressure testing machine. Understand their operation, safety features, and maintenance requirements.

- Safety Gear: Wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and hearing protection if necessary.

- Location: Set up the equipment in a well-ventilated area away from flammable materials or open flames.

- Secure the Equipment: Ensure that the air compressor skid is stable, properly leveled, and securely anchored to prevent any accidents.

- Pressure Limits: Always operate within the specified pressure limits of both the hose and the testing equipment.

- Inspect Hoses: Examine the hoses to be tested for signs of damage, wear, or aging. Do not test hoses that are visibly compromised.

Step-by-Step Instructions on How to Use an Air Compressor Skid with a Hose Pressure Testing Machine

- Prepare the Air Compressor Skid

- Ensure the air compressor skid is properly positioned on a level surface.

- Secure the skid in place to prevent movement during operation.

- Connect the Air Compressor Skid to a Power Source

- Plug in the air compressor skid to a suitable power source, following manufacturer instructions.

- Turn On the Air Compressor Skid

- Switch on the air compressor skid and allow it to build up the required operating pressure, as indicated by the pressure gauge.

- Connect the Hose Pressure Testing Machine

- Use a high-pressure hose to connect the outlet of the air compressor skid to the inlet of the hose pressure testing machine.

- Ensure all connections are tight and secure, checking for any air leaks.

- Prepare the Hose to be Tested

- Inspect the hose for any visible signs of damage, such as cracks, bulges, or wear.

- If the hose is damaged, do not proceed with the test. Repair or replace it as needed.

- Close the Valve at the Outlet of the Hose Pressure Testing Machine

- Ensure that the testing machine’s pressure release valve is closed.

- Apply Pressure to the Hose

- Slowly open the valve at the outlet of the hose pressure testing machine to start pressurizing the hose.

- Gradually increase the pressure until it reaches the desired test pressure.

- Monitor the Hose for Leaks

- Carefully inspect the entire length of the hose for any signs of leaks, including bubbles or hissing sounds.

- If you detect any leaks, stop the test immediately and address the issue.

- Maintain the Test Pressure

- Keep the hose pressurized for the required test duration, which varies depending on the type of hose and testing standards.

- Release the Pressure from the Hose

- After completing the required test time, slowly close the valve at the outlet of the hose pressure testing machine to release the pressure.

- Disconnect the Hose

- Once the pressure has been released, disconnect the hose from the hose pressure testing machine.

Conclusion

Using an air compressor skid with a hose pressure testing machine is a vital process for ensuring the safety and reliability of hoses and pipelines. By following the outlined steps and taking the necessary safety precautions, you can identify potential issues before they become critical problems. Remember that a passed test indicates a safe hose for use, while a failed test necessitates repair or replacement to maintain safety standards and prevent costly incidents in various industries.