ABOUT US

Wingoil is a professional manufacturer of high-pressure equipment and a flow control solution provider in the oil & gas industry.

Located in Chongqing, China, Chongqing Weiyun Technology Development Co., Ltd. (WINGOIL) is a professional manufacturer of high-pressure and flow control equipment for the oil and gas industry.

Wingoil has research and development, design, and manufacturing technology for special equipment in oil and gas exploration and development and provides a full range of technical services. With years of experience in equipment R&D and manufacturing, as well as in technical solutions.

Wingoil provides customers with one-to-one customized products and services based on actual customer needs. Wingoil supplied products to leading oil and gas companies such as PetroChina, Sinopec, CNOOC, Shell, Mobil, Chevron, etc.

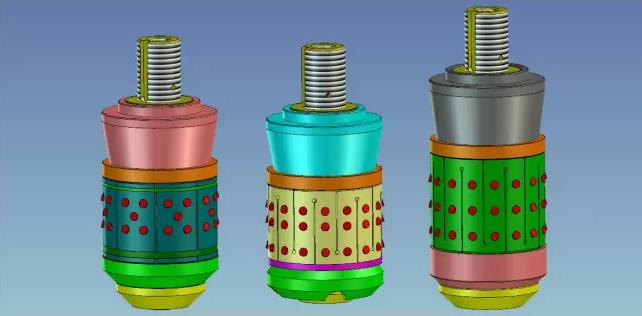

Products:

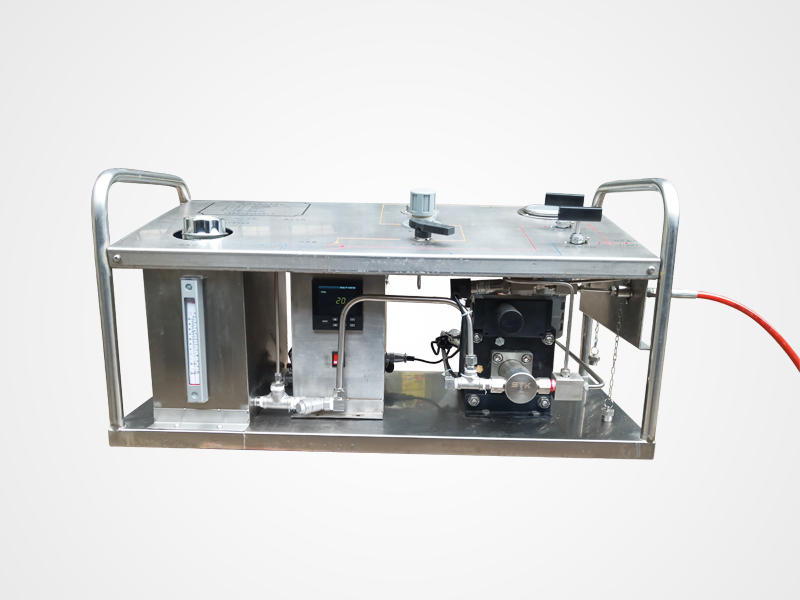

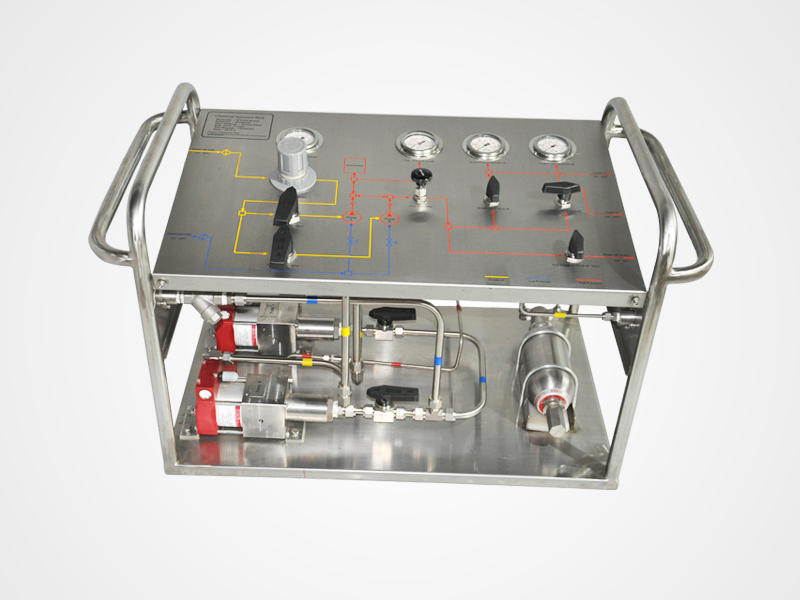

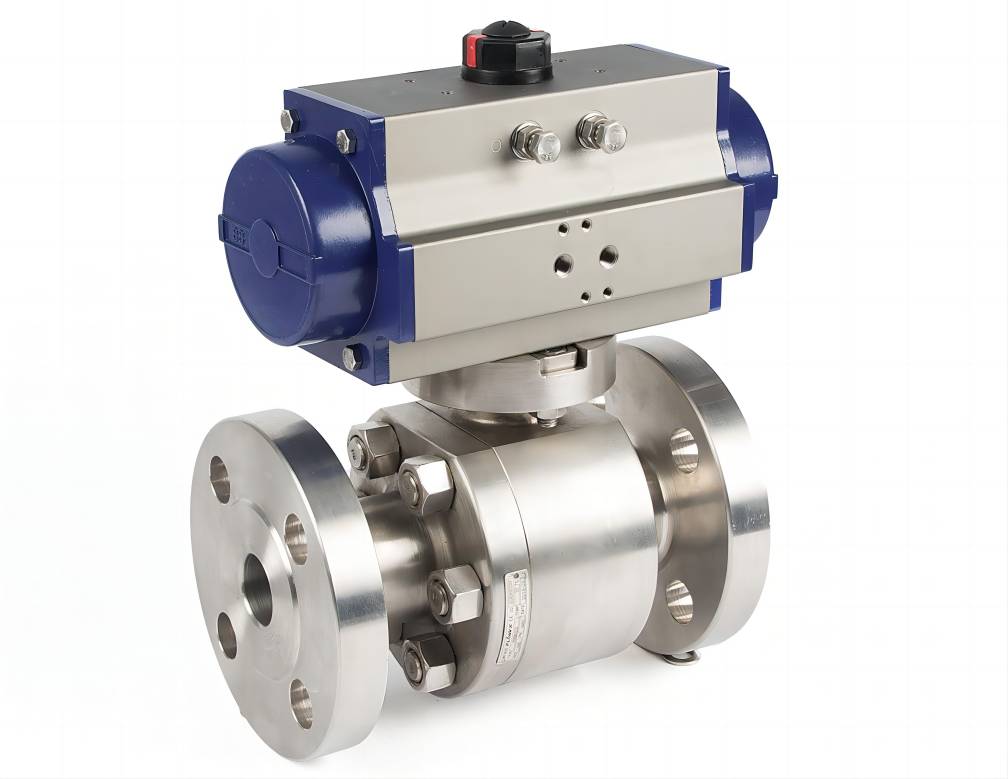

High Pressure and Flow Control

Equipment Range for the Oil and Gas Industry

Hydro test pump manufacturers with unrivaled expertise in high-pressure and flow control solutions, Wingoil’s products are widely used in the oil and gas industry for offshore and onshore applications.

Solution

High Pressure and Flow Control

Custom Engineered Solutions in the Oil & Gas Industry

Wingoil provides high pressure and flow control custom-engineered solutions in the Oil & Gas industry. Cutting-edge designs, quality, and rugged durability have won us a worldwide reputation as a first-class product that ensures years of trouble-free service.

Project Support

Site Services in the Oil & Gas Industry

Wingoil’s excellent service and expertise don’t end at our facilities. Our staff can provide mechanical, hydraulic, and assembly services in the oil & Gas industry.

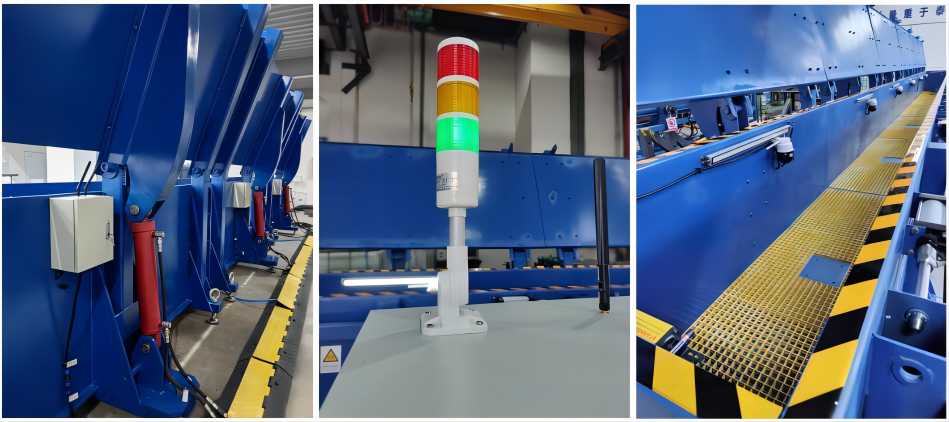

Our Project

Video

High-flow high pressure testing machine with PC & Chart recorder

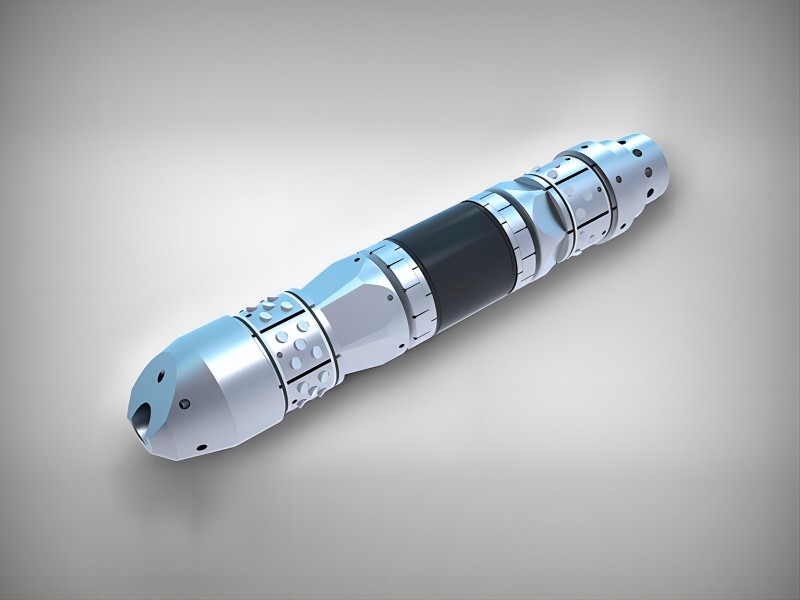

Installation Bridge Plug

Lifting Anti-nozzle And Wellhead

Pressure testing machine with Chart Recorder