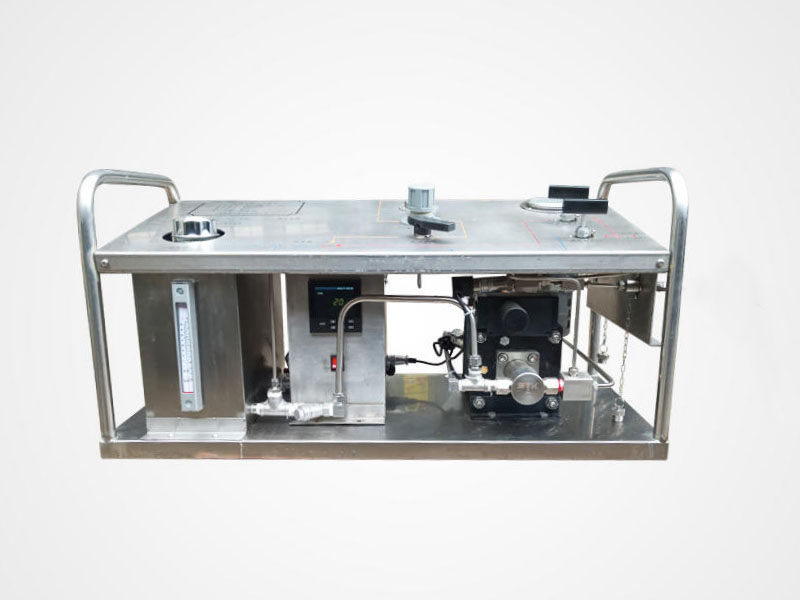

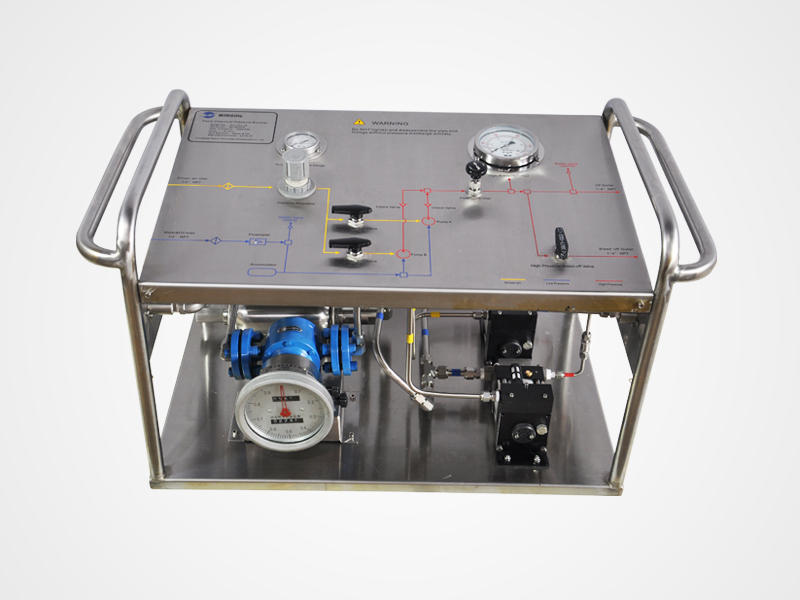

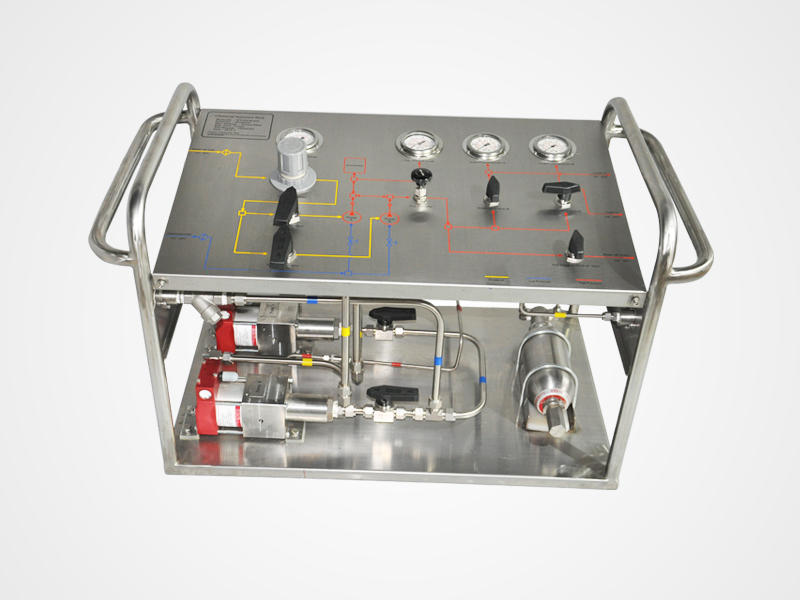

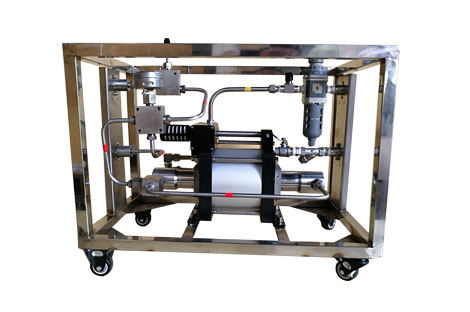

WINGOIL uses advanced technology for Hydrostatic Pressure Test Pump, WINGOIL can guarantee the accuracy and reliability of test data and the safety and controllability of testing. Under the guidance of the market, WINGOIL continues to innovate and improve technology to provide customers with safe and reliable pressure test equipment. We can also offer on-site equipment commissioning services to improve customer satisfaction.